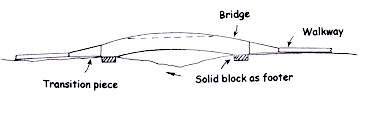

| Making curved structures out

of lumber can be challenging but quite rewarding. This picture shows a

flowing walk leading over a curved bridge in the front courtyard of a

home.

The walkway is easy to construct because you use ground contact treated lumber, (.40 cca) supported by the ground.

|

|