![]()

By Tim Johnson

You don't need a dream shop to build

this project.

You don't need a dream shop to build

this project.

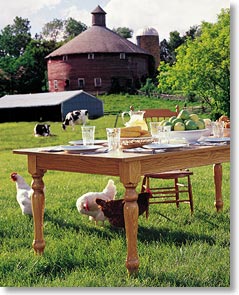

Aside from feeding the

occasional flock (whenís the last time you had eight dinner guests?), a big

surface where you can spread things out is invaluable, for computing, writing,

hobbies or for kidsí activities. A large table is the perfect gathering place

for todayís open kitchens and great rooms, and you can build this one even if

you donít have a dream shop with lots of huge machinery.

This table is made from white ash, a hardwood thatís beautiful, durable and affordable. The top floats on a base thatís built to last. Strong joinery between the legs and aprons is accomplished using an innovative and inexpensive commercial jig. Internal supporting rails are dovetailed to stiffen the structure, yet you can make and install them in minutes. And donít worry about the huge top. Iíll show you how to manage gluing it all together, but only after Iíve shown you how to edge-joint its long boards perfectly without using a jointer!

|

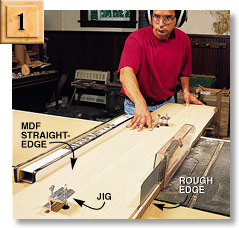

RIP

STRAIGHT EDGES easily with inexpensive straightlining jigs (see Sources,

page 77). One thumbscrew on each jig holds the rough-edged board, the other

grips an 8-ft. long by 7-in. wide MDF straightedge. After straightlining one

edge, remove the board from the jig and rip the other edge parallel. (You can

also have straightlining done for you at the lumberyard.) |

†![]()

You donít

have a battleship-sized jointer? Fine! Get perfect edge joints on these long

boards using a router instead.

Youíll need a tablesaw, a

router that accepts 1/2-in. bits, four router bits, an electric drill (a drill

press is very helpful, but not absolutely necessary), a BeadLOCK doweling jig

(see Sources, page 77), a jig for ripping a straight edge

on rough lumber, sawhorses and assorted clamps. In addition to the lumber

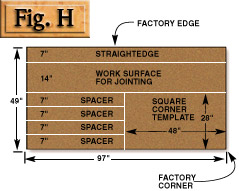

($450), buy two 4x8 sheets of 3/4-in. medium density fiberboard (MDF) ($50).

One serves as a work surface and the other provides the straightedges for

jointing and squaring operations (see Fig. H, Photos 3 through 5 and 10). You wonít need a jointer. You donít have to

own a planer either, because most hardwood lumberyards will mill rough lumber

for you. Youíll need a lathe if you want to turn your own legs. There are

ready-made alternatives if you donít ($35 to $75 each, see Sources, page 77).

![]()

|

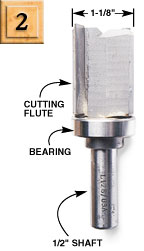

A

BIG PATTERN-CUTTING BIT works best for jointing edges. Its large cutting

diameter leaves smooth, chatter-free surfaces. |

|

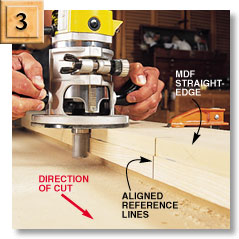

ROUT

THE FIRST EDGE of each joint, using the pattern-cutting bit and an 8-ft.-long

MDF straightedge. After laying out the boards for the top, draw a line across

each joint, halfway from the end. Aligning these lines with a similar line at

the midpoint of the MDF guarantees that the jointed edges will fit together. |

|

JOINTING

WITH A ROUTER |

†The top, aprons and internal support rails are

made from 8-ft. long 5/4 boards, about 80 bd. ft., milled to 1-in. thickness.

If youíre having your lumber milled at the yard, have them also make a straight

cut on one edge (called SL1E or "straightlining"). Milling and

straightlining cost only about 30 cents per ft. and save you the trouble of

doing it yourself (Photo 1).

If 5/4 boards arenít

available, substitute 100 bd. ft. of 6/4. You could also use 4/4 stock and

rework the dimensions for 3/4-in. material. A 3/4-in.-thick top will be lighter

in weight and appearance (maybe too light for your taste), and the splines will

have to be no wider than 3/16-in. The thinner, 6-ft.-long aprons will be more

likely to sag. Youíll also have to use smaller loose tenon stock and a

different BeadLOCK drilling jig that requires drilling more, albeit smaller

holes.

Use 8/4 stock for the legs,

milled to 1-3/4-in. thickness, cut into 30-in. lengths, and glued up. Youíll

need about 25 bd. ft.

White ash looks similar to

oak, with one noticeable difference. Its heartwood is a dark brown color that

contrasts sharply with its light-colored sapwood. When choosing or ordering

lumber, look or ask for pieces that are all sapwood, especially the 8/4 stock

for the legs. The 5/4 stock must have one good sapwood face. Heartwood on the

back side wonít show, except on the edges of the top.

Youíll need twelve 5/4

boards that are at least 7-in. wide. Use the seven that look the best together,

considering grain pattern and color, for the top (seven boards 6-in. wide after

jointing will make a 42-in. wide top). The four aprons, including their add-on

half-round details, require three of the remaining boards (you can get the four

pieces for both short aprons from one board). Use one of the two remaining

boards for the internal rails and the other for splines and test pieces.

Make the top first. Donít

worry about making it to exact dimensions. Just use your best-looking boards

and come as close as you can. (My top turned out to be 41-1/2-in. wide). Then

adjust the size of the base, changing the lengths of the aprons to maintain the

overhang of the top.

Splines align

the boards in the top, so you donít spend hours sanding the joints flush later.

|

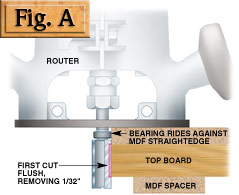

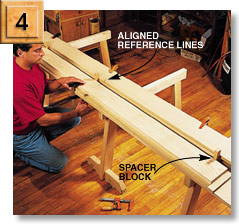

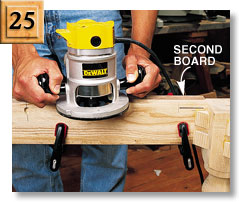

USE THREE SPACER BLOCKS to position the second board for routing and

clamp it in place. Make the spacers 1/32-in. narrower than the cutting

diameter of the pattern bit, so the second routing pass will remove only 1/32

in. from the board. |

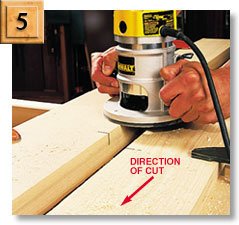

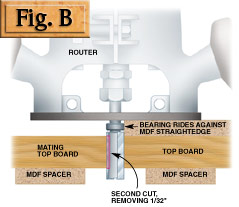

ROUT THE MATING EDGE of each joint, while keeping the router firmly

held against the straightedge. Because the cut is made opposite the bearing

point, the edge will be ruined if the bit wanders away. |

|

JOINTING WITH A ROUTER |

|

|

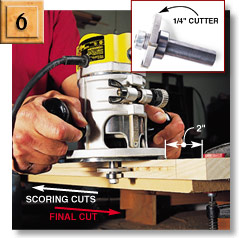

ROUT THE 1/2-IN.-DEEP GROOVE for the spline in several passes, using a

1/4-in.-wide slot-cutting bit (above).Tip: To avoid tear-out, make a couple

light scoring cuts, about 1/8-in. deep, moving from right to left. Then move

left to right, full depth. Stop the cut 2-in. from each end of the board, so

it wonít show. |

|

|

TEST FIT the spline. It should slip into the groove freely, but

without being loose. It can be one long piece or several short ones. Rounded

ends match the ends of the slot. Dry fit each joint to make sure the spline

fits inside without binding. |

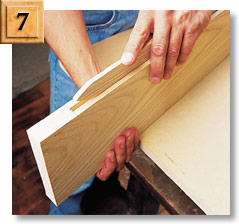

STACK THE BOARDS as you glue them. Put a bead of glue at the bottom of

the groove of the first board and add the spline. Roll a layer of glue onto

the edge of the adjacent board, add a bead in its groove and assemble the

joint. Donít put any glue on the splines. The glue causes them to swell and

make the joint impossible to fit. Glue the top together in stages, two to

four joints at a time. |

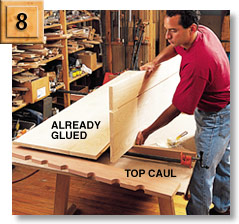

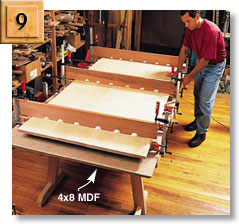

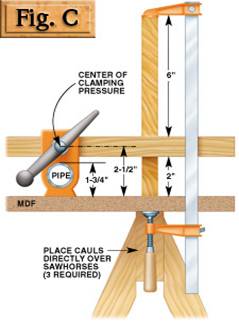

Three

pairs of cauls make gluing the huge top manageable and guarantee that it will

be flat.

Donít

worry about chopping mortises or trying to cut tenons on the ends of the

6-ft.-long aprons. With the new BeadLOCK system, all you need for

mortise-and-tenon style joinery is a drill and a bit

|

CLAMP THE CAULS to the work surface with the top sandwiched between

(see Fig. C).

Then tighten the pipe clamps, starting at the center and working out to the

ends. Remove the glue squeeze-out at the joints after it sets up, but before

it hardens. After gluing, trim the long edges with the router and

straightedge so theyíre straight and parallel. |

|

|

CAULS FOR GLUING THE TOP |

|

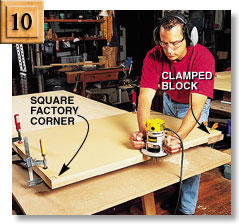

SQUARE THE END of the top, using a piece of MDF with a factory corner

as a template. If you have more than 1/4 in. to remove, use a saw first, to

get close. Align one edge of the MDF with the long side of the top. Clamp a

block against the opposite edge of the top to avoid blowout. Then trim the

edge square, making shallow passes with the pattern-cutting router bit. |

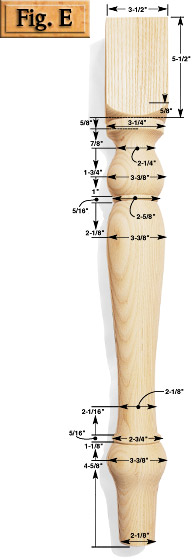

LEG PROFILE AND

DIMENSIONS |

|

TURN THE LEGS from laminated 3-1/2-in. square blanks, using the

dimensions from Fig. E,

or order the legs through the mail (see Sources,

page 77). If you want to turn them yourself, see "Turning Table

Legs" on page 42. |

|

|

|

|

|

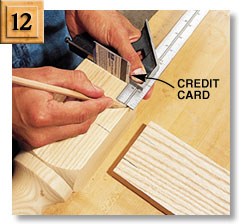

MARK REFERENCE LINES for the BeadLOCK jig on the legs and aprons.

Offset the centerlines on the leg by the thickness of a credit card. This

slightly raises the rail above the top of the leg, allowing you to plane the

apron flush after assembly (see Photo 16). |

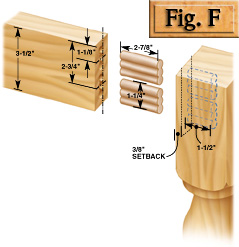

EXPLODED VIEW OF LEG AND APRON JOINERY |

|

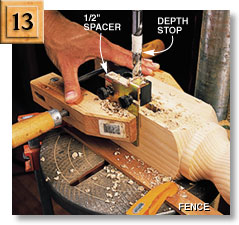

DRILL THE LEGS. Use a shop-made 1/2-in.-thick spacer in the BeadLOCK

jig to locate the holes properly. A drill press works great for this

operation. Itís easier, faster and more accurate than drilling by hand. |

DRILL THE APRONS from the end so you can be sure the holes go in

straight. If the holes arenít straight, the tenons will be angled and the

joint wonít fit. Center the drill on your body and sight down the apron while

drilling. |

|

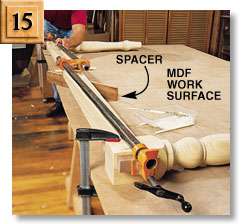

GLUE THE LONG SIDES FIRST. Avoid a twisted glue-up by clamping the

legs flat to the MDF before you tighten the pipe clamps.Use a spacer to keep

the apron from sagging under the weight. |

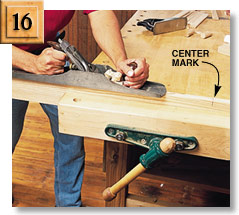

PLANE THE APRONS flush with the top of the legs, working from each end

to the center. Itís OK to leave the apron slightly crowned at its center, so

the top doesnít appear to sag. |

|

APPLY A TOURNIQUET to square the base after final assembly. Do this

before the glue sets. Shorten the longer side by adding tension until both

diagonals measure the same. |

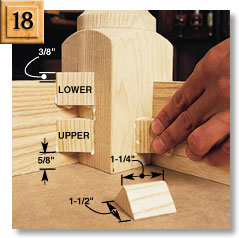

TWO SHORT BLOCKS reinforce each joint. The upper blocks leave room for

top fasteners. The lower blocks extend and serve as stops for the half-round

detail. |

|

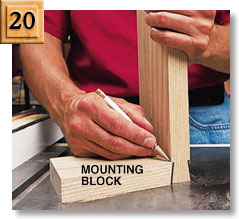

MAKE ANGLED CUTS on the end of the rails, using a tenoning jig, with

the blade height slightly less than the thickness of the mounting block. Then

raise the blade and crosscut the mounting blocks at the same angle. |

LOCATE THE SHOULDER of the railís dovetail by using the mounting

block. Then cut the shoulder square, keeping the blade low enough so it

doesnít cut into the dovetail. |

|

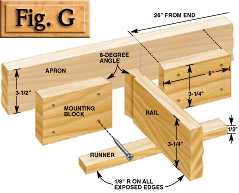

GLUE THE RUNNER in place after the first mounting block has been glued

and screwed square to the apron. Itíll hold the rail at exactly the right

height. The runner extends below the apron, just like the corner blocks. |

CAPTURE THE DOVETAILED RAIL between the mounting blocks. After

applying glue, set the rail on the runner and snug it against the first block.

Then slide the second block tight against the rail and fasten it. |

|

Dovetailed

braces strengthen the base, support the top and keep the long aprons from

bowing and twisting. |

|

|

INTERNAL RAIL ASSEMBLY |

|

|

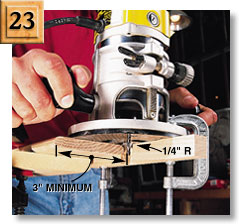

MAKE HALF-ROUND molding for the aprons. Round the edges of

1/2-in.-thick stock with a 1/4-in. round-over bit. After routing, rip the

stock into separate 1-1/4-in.-wide pieces. |

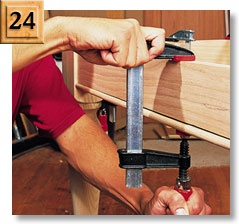

GLUE THE HALF-ROUND MOLDINGS to the aprons. Cut them slightly long and

spring them between the legs, pressed against the corner blocks and runners

that hang below the apron. Theyíll stay in place while you reach for the

clamps. |

|

ROUT SLOTS for the tabletop fasteners, using a 1/8-in. slot cutter

(see Sources).

Make a wider surface to support the router by clamping a second board to the

apron. |

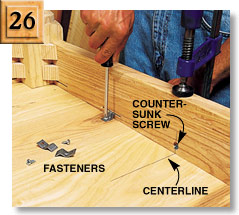

ATTACH THE BASE. Allow for seasonal movement of the top by using

screws at the center of each short apron and support brace and S-shaped metal

fasteners everywhere else (see Sources).

To position the base for fastening, align centerlines drawn on each of its

sides with corresponding lines drawn on the top. Then clamp the base in place. |

|

|

|

|

CUTTING DIAGRAM FOR MDF |

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||