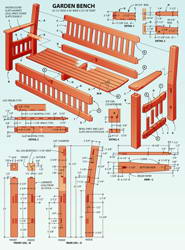

| Garden Grace |

| How to build a classic cedar

garden bench. |

| TEXT AND PHOTOS BY NEAL

BARRETT |

|

|

|

|

|

|

|

|

|

|

If the only thing you do in your yard is mow the

lawn, maybe it's time to add some creature comfort to

your outdoor space. Our stately cedar bench is ideal for

relaxing in the fresh air, enjoying the greenery and

just getting away from it all. And, it's more than just

a great place to sit. Featuring a design influenced by

the Arts & Crafts style, the piece will bring an upscale

look to any yard. Best of all, the construction details

are solid and simple, giving you a long-lasting piece of

outdoor furniture that's relatively easy to build.

We used red cedar for the bench--a material that's

generally available at lumberyards and home centers

throughout the country. Since cedar is widely used for

outdoor decking and trim, it's usually not kiln-dried

and is often sold with a high moisture content. For the

best results with this project, buy the material at

least two to three weeks before beginning construction.

Stack the lumber in a dry location with spacers between

the boards, allowing for good air circulation so the

material will dry. And, be sure to use a glue designated

for exterior use. We used Titebond II to assemble our

bench. | |

|

|

|

|

|

|

|

|

|

Нажмите для увеличения

|

|

|

| MATERIALS LIST--GARDEN BENCH |

| Key |

No. |

Size and description (use) |

| A |

2 |

2-3/4 x 5 x 35-1/2" cedar (rear

leg) |

| B |

2 |

2-3/4 x 2-3/4 x 23-1/2" cedar

(front leg) |

| C |

2 |

1 x 3 x 51" cedar (back rail) |

| D |

2 |

1 x 4 x 51" cedar (seat rail) |

| E |

1 |

1 x 2-1/2 x 51" cedar (front

rail) |

| F |

2 |

1 x 2-1/2 x 17-3/8" cedar (side

rail) |

| G |

2 |

1 x 3-1/4 x 17-3/8" cedar (side

rail) |

| H |

1 |

1-1/2 x 3-3/8 x 17-3/8" cedar

(center rail) |

| I |

22 |

3/8 x 1-1/2 x 6-1/4" cedar

(bottom slat) |

| J |

14 |

3/8 x 1-1/2 x 8-3/4" cedar (back

slat) |

| K |

6 |

3/4 x 2-1/4 x 54-1/2" cedar (seat

slat) |

| L |

2 |

1 x 4-1/4 x 20-5/8" cedar (arm) |

| M |

36 |

1-1/2" No. 8 fh woodscrew |

| N |

36 |

3/8"-dia. cedar plug |

| Misc.: Exterior

glue; 120-grit sandpaper; Cabot No. 1400 Decking

Stain, Clear (Samuel Cabot Inc., 100 Hale St.,

Newburyport, MA 01950; www.cabotstains.com). | |

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

|

Preparing The Legs

The 2-3/4-in.-thick legs

are made by gluing together thinner stock. To make each

rear leg, crosscut a pair of 2 x 6 cedar pieces to about

40 in. Use a roller to spread glue on the mating

surfaces of the boards (Photo 1) and clamp the pairs

together to form the leg blanks. For the front legs,

follow the same procedure with 30-in.-long 2 x 4 stock.

When the glue dries, rip the rear blanks to a width

of 5 in. and use a band saw to trim them to 2-3/4 in.

thick. Then saw the front legs to 2-3/4 in. square.

Plane the cut surfaces smooth and crosscut the front

legs to finished length.

Lay out the side profile of the rear legs on the

cedar blanks (Photo 2) and cut to the waste side of the

lines with a band saw (Photo 3). Then plane the sawn

surfaces (Photo 4). Use a sanding block or scraper to

smooth the inside corner of each leg where the plane

won't reach.

Use a plunge router with a spiral up-cutting bit and

an edge guide to remove most of the waste in each leg

mortise (Photo 5). Square the mortise ends with a sharp

chisel (Photo 6).

Notice that the arm mortises in the rear legs are cut

at a 7-1/2° angle to allow the arms to be level. To

start the angled mortises, clamp a block with a square

end to the vertical face of a leg and use it as a guide

to drill out most of the waste (Photo 7). Then, use a

sharp chisel to finish each mortise. Crosscut the top

end of each rear leg so that it's square to the angled

face of the leg. Chamfer the ends with a block plane

(Photo 8). |

|

| Apply glue to pairs of 2 x 6s, and then

clamp them together to form the rear leg blanks. Use

2 x 4s for the front legs. |

| Band saw the rear leg blanks to 5 in.

wide and 2-3/4 in. thick. Plane them smooth and lay

out the side profile. |

| Use a band saw to cut the rear legs from

the blanks. Be sure to keep the saw kerf on the

waste side of the layout line. |

| Use a sharp plane to smooth the sawn

surfaces. Switch to sandpaper or a scraper at the

back inside corner. |

| Mark the mortise locations on the front

and rear legs, and use a plunge router and edge

guide to make the cuts. |

| After the routing has been completed,

use a sharp chisel to square the rounded ends of

each leg mortise. |

| To cut the angled arm mortises, clamp a

board to the leg to act as a guide. Bore holes, then

finish with a chisel. |

| Crosscut the leg top so that it's square

to the angled face of the leg. Use a chisel or block

plane to chamfer the end. |

|

|

|

| |

|

|

Bench Rails

Rip and crosscut 1-in.-thick

stock for the rails. Also, cut a piece of 2 x 4 stock to

size for the center seat-support rail. Use a scrap stick

as a beam compass to mark the 39-3/4-in. radius on the

top side rails and center rail, but don't cut the curves

at this point. Install a dado blade in the table saw and

cut the tenons on the ends of the side, front and back

rails (Photo 9). Use the table saw rip fence as a stop

to ensure that the tenons are of equal length. Readjust

the blade height to cut the shoulder at the top and

bottom edge of each tenon.

Clamp a scrap fence to the table saw fence and

position it so that only 1/2 in. of the dado blade will

be exposed. Turn on the saw and raise the blade to a

height of 7/8 in., and cut the tenons on the top ends of

the front legs (Photo 10). Readjust the saw again to cut

the tenons on the ends of the center seat-support rail.

Next, mark the locations of the slat mortises in the

side, front and back rails and use a plunge router to

cut them (Photo 11). Since the rails are narrow, clamp a

second board to the workpiece to help support the router

base. Square the mortise ends with a sharp chisel. Work

carefully when making these cuts, as there are no

shoulders on the slats to hide oversize mortises.

Lay out the mortises for the center seat-support rail

in the front and back rails. Use a Forstner bit in a

drill press to remove most of the waste (Photo 12), and

square with a chisel. Then, cut the curved profiles on

the side and center support rails, and rip and crosscut

the bench slats to finished size.

Assembly

Begin assembly by joining a set of

slats to the side rails (Photo 13). It isn't necessary

to glue the slats in place since they will be held

captive between the rails, but if they fit too loosely,

you can place a spot of glue in the mortises to prevent

them from rattling.

Spread glue in the leg mortises and on the side rail

tenons, assemble one of the bench sides, and clamp until

the glue sets (Photo 14). Repeat the process for the

other side. |

|

| Use a dado blade in the table saw to cut

the rail tenons. The rip fence acts as a stop to

ensure tenons of equal length. |

| To cut the tenons on top of the legs,

raise the dado blade into a scrap fence to yield a

1/2-in.-wide x 7/8-in.-high cut. |

| Rout the slat mortises in the bench

rails. Clamp a second board to the workpiece to help

support the router base. |

| Mark the mortise locations for the

center seat-support rail. Use a Forstner bit to

remove most of the waste. |

| After cutting the curved rail profiles,

press the side slats firmly into their mortises.

It's not necessary to use glue. |

| Spread glue in the leg mortises and side

rail tenons, and assemble one of the bench sides.

Clamp until the glue sets. |

|

|

|

| |

|

|

Join the slats to the front rails. If necessary, use

three or four clamps to press the slats all the way into

the joints (Photo 15). Then, spread glue in the front

and back rail mortises and on the center rail tenons,

and join the parts (Photo 16). Use a clamp to pull the

joints tight, and set the assembly aside to let the glue

dry (Photo 17).

Assemble the back rails and slats and join this

subassembly to one of the bench sides (Photo 18). When

the glue cures, join the front and back seat rail

assembly to the same side. Complete the bench frame by

joining the opposite side to the rail ends.

Rip and crosscut 3/4-in. stock to size for the seat

slats. Adjust the table saw blade angle to 9-1/2° and

bevel one edge of the front and back slats. Leave the

rest of the slat edges square. Use a combination bit to

bore screw pilot holes and 3/8-in.-dia. x 5/16-in.-deep

counterbores in the seat slats. Then, fasten the slats

with galvanized deck screws. Maintain an equal space

between the slats. Use a 3/8-in. plug cutter in your

drill press to cut screw plugs in a cedar board (Photo

19). Then, spread glue in the screwholes and on the

plugs, and insert a plug into each hole (Photo 20). When

the glue dries, pare each plug flush.

Rip blanks to 4-1/4 in. wide for the arms, and

crosscut them a few inches longer than finished length.

Use a dado blade in your table saw to cut a square

shoulder tenon on the end of each blank. Then, lay out

the angled shoulder and cut the finished tenon with a

sharp backsaw (Photo 21). Refine the cuts with a sharp

chisel where necessary. With the tenons done, crosscut

the arms to finished length.

Mark the location of the mortise on the underside of

each bench arm, and use your drill press with a Forstner

bit to bore overlapping holes that remove most of the

waste. Then, use a sharp chisel to square the mortise

walls. Note that the arm mortise is elongated so the

tenon at the opposite end of the arm will easily slide

into the leg mortise.

Lay out the finished shape of the arms on the blanks

and cut to the lines with a band saw. After smoothing

the sawn edges, join the arms to the bench using two

clamps to ensure pressure is applied to both joints

while the glue sets (Photo 22).

Finishing

Sand the bench with 120-grit

sandpaper. Brush off all sanding dust before applying a

finish. We applied a coat of Cabot Clear Decking Stain

to our bench. This finish is easy to apply and provides

good protection for outdoor pieces. Brush on a liberal

coat and allow it to dry for at least 24 hours before

using the bench. |

|

| Use three or four clamps to squeeze the

front rail assembly, pressing the slats to the

bottom of the mortises. |

| Spread glue in the shallow center rail

mortises and on the seat-support rail tenons. Then

join the parts. |

| Use a clamp to pull the front rail and

back rail assembly tight to the center seat-support

rail. |

| Join the back to one of the bench sides.

When the glue cures, add the front and back seat

rail assembly to the same side. |

| Use a plug cutter to make cedar plugs to

cover the seat screws. Pop the plugs free with a

flat-tip screwdriver. |

| Spread glue in the holes and on the

plugs and place a plug into each hole. Pare each one

flush with a sharp chisel. |

| After cutting square tenons at the arm

ends, use a backsaw to cut the angled shoulders.

Refine tenons with a chisel. |

|

|

| |

|