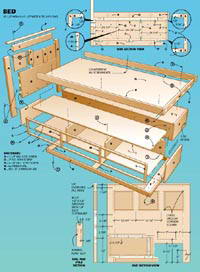

| BED AND STORAGE BOXES |

| A platform bed that's more than

just a place to sleep. |

| TEXT AND PHOTOS BY NEAL

BARRETT |

|

|

|

Íàæìèòå äëÿ óâåëè÷åíèÿ

|

Beds are for sleeping, right? Well, not if you're a

kid. If you're a kid, bed is the place to read, dream,

plot and scheme—or just while away a rainy afternoon.

It's gossip central after school is out and the

intensive care unit during a bout with the flu. It's the

place to return to when the day is done—and sometimes,

it's just the best place to be alone.

Now that you know it's special, the job is to build a

bed that's up to snuff. Our design takes care of all the

basics, with a little extra just for fun. It's made of

plywood and poplar and we've designed it to go together

without a cabinet shop full of clamps. Underneath,

there's ample storage, with enough space for a pile of

games, books and the family cat. As for good looks,

we've incorporated a strong but simple visual theme that

matches the rest of our bedroom suite. | |

|

|

|

|

|

|

|

| 10--Use your

worktable as a registration surface when cutting the

slots in the storage box partition panels. | |

|

|

|

|

| 12--With all parts

aligned, bore screwholes through the top and secure the

panel. Turn the assembly over and fasten the bottom. | |

|

|

|

|

|

|

MATERIALS LIST–BED

|

| Key |

No.</ B> |

Size and description (use) |

| A |

2 |

1 1/2 x 3 1/2 x 38 3/4" poplar (stile) |

| B |

2 |

1 1/2 x 3 1/2 x 9" poplar (mullion) |

| C |

1 |

1 1/2 x 3 1/2 x 34" poplar (rail) |

| D* |

1 |

1 1/2 x 16 3/4 x 34" poplar (rail) |

| E |

3 |

3 1/2 x 10 x 10" plywood (panel) |

| F |

1 |

3/4 x 2 x 41 1/2" poplar (cap) |

| G |

4 |

3/4 x 9 x 18 1/4" plywood (divider) |

| H |

2 |

3/4 x 9 x 74 1/4" plywood (back) |

| I |

4 |

3/4 x 19 x 74 1/4" plywood

(top/bottom) |

| J |

4 |

3/4 x 10 1/2 x 19" plywood (end) |

| K |

4 |

3/4 x 7/8 x 74 1/16" poplar (facing) |

| L |

4 |

3/4 x 7/8 x 10 9/16" poplar (facing) |

| M |

4 |

3/4 x 7/8 x 81 3/16" poplar (facing) |

| N |

2 |

3/4 x 2 3/4 x 73 1/4" plywood (toe

kick face) |

| O |

2 |

3/4 x 2 3/4 x 33" plywood (toe kick

end) |

| P |

3 |

3/4 x 3 1/2 x 33" plywood (cleat) |

| Q |

1 |

3/4 x 39 1/2 x 75 3/4" plywood

(platform) |

| R |

2 |

3/4 x 3 1/2 x 76 1/2" poplar (platform

edge) |

| S |

1 |

3/4 x 3 1/2 x 39 1/2" poplar (platform

end) |

Misc: Misc.: No. 20 joining

plates; 2 1/4" No. 10 fh woodscrews; 2" No. 8 fh

woodscrews; 11/4" No. 8 fh woodscrews; 6d finish nails;

glue; sandpaper; latex primer and enamel.

Note: All

plywood birch veneer

*Laminate from narrower stock

| |

|

| |