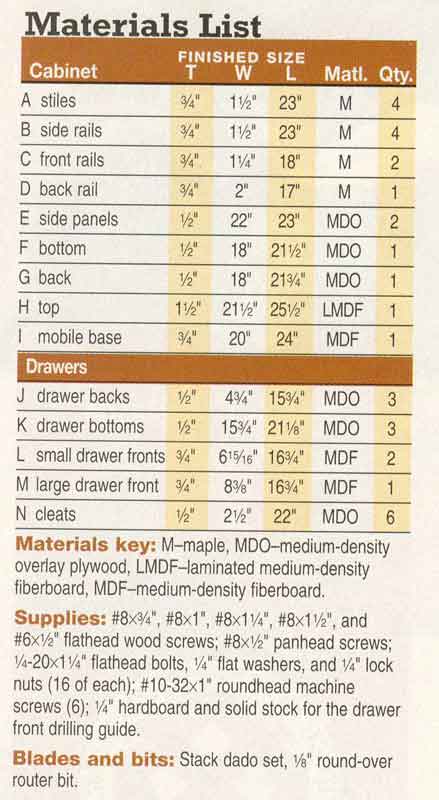

Inexpensive materials and basic joinery make for speedy construction of this hardworking shop cabinet. Even the drawers won't slow you down. With their special side/slide hardware, they practically build themselves.

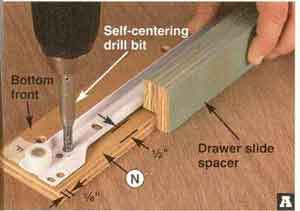

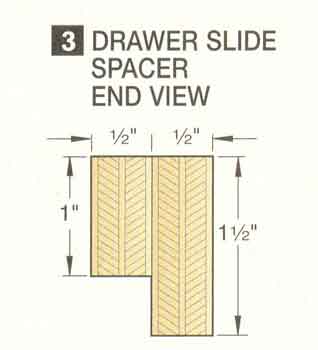

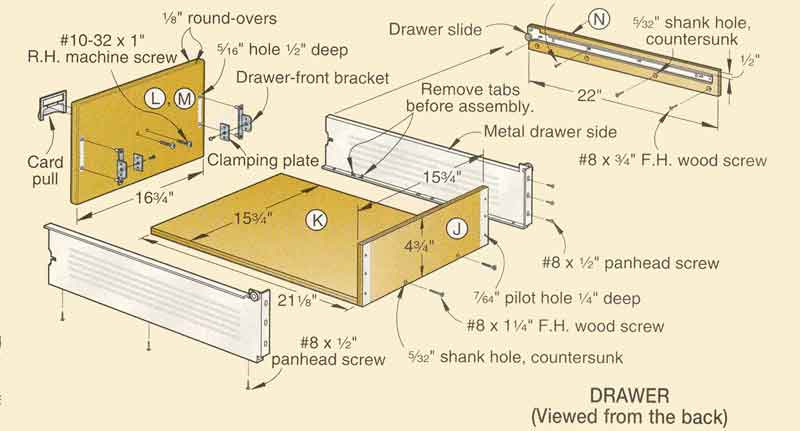

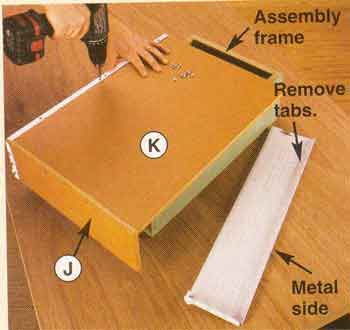

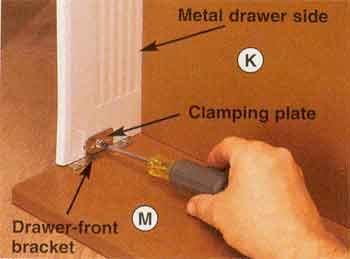

If saving time and money is important to you, you'll really appreciate the drawer hardware used in this project. Costing little more than standard slides, this epoxy-coated steel hardware combines both drawer side and slide in one piece. For more on this innovative hardware, see "Make the fastest drawers in the west (or east)" on page 76.

Start with the case

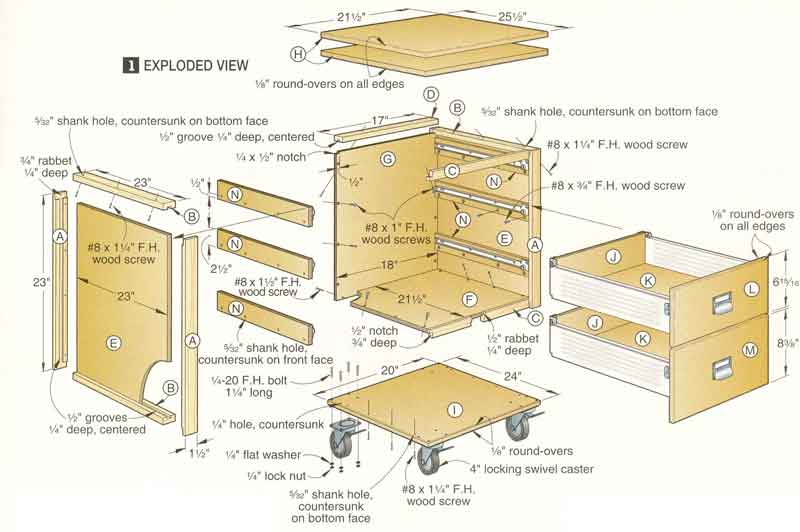

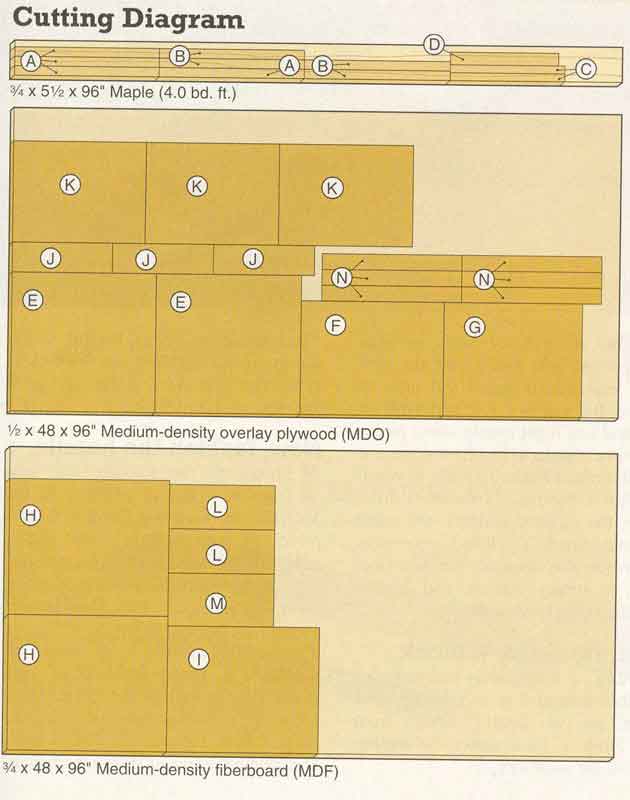

1 Cut the stiles (A), side rails (B), front rails (C), and back rail (D) to the sizes listed in the Materials List. With a dado blade adjusted to match the thickness of the 1/2" plywood side panels (E), cut centered grooves in parts A, B, and D, where shown on Drawing 1. Then cut the 1/4"-deep rabbet along the top edge of the lower front rail (C) and the 1/2" notches 3/4" deep in both front rails. Now cut the rabbets in the stiles (A). Finish-sand all the parts to 180 grit.

2 Cut the side panels (E) to the size listed. Glue and clamp the stiles and rails (A, B) to the side panels, checking the assemblies for square.

3 Cut the bottom (F) and back (G) to the sizes listed. Cut the 1/4x1/2" notches in the back's top corners.

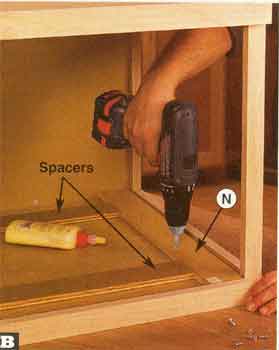

5 Place the first side assembly (A/B/E) flat on a horizontal surface. Squeeze a bead of glue on the side panel along the rear stile and the lower side rail. Place the bottom/back assembly (C/F/D/G) on the side assembly, and clamp it in place. Now drill angled countersunk screw holes through the bottom and back and into the rear stile and the lower side rail. Drive the screws.

6 Apply glue to the upward-facing edges of the bottom and back panels. Position the second side assembly, and clamp it in place. Turn the cabinet over. Then, as before, drill angled countersunk screw holes, and drive the screws.